Holography

Most of us know holograms as three dimensional pictures in which objects and scenes appear to have depth and perspective. In the arts, holograms are used to create 3D images of great originality and vividness. Commercial uses of holograms include 3D security tags on up-scale products and anti-counterfeiting pictures on credit and cash cards. Many countries embed holograms in their banknotes as anti-counterfeiting devices.

But not all holograms portray objects. Holograms can have unique, often extraordinary functional properties. META designs and fabricates holograms as specialty optical elements that can not only replace traditional lenses and mirrors but can provide optical functions that are very difficult to achieve with conventional optics. These holographic optical elements (HOEs) allow system designers to develop devices that are smaller, lighter, cheaper and better than those achieved with conventional optics.

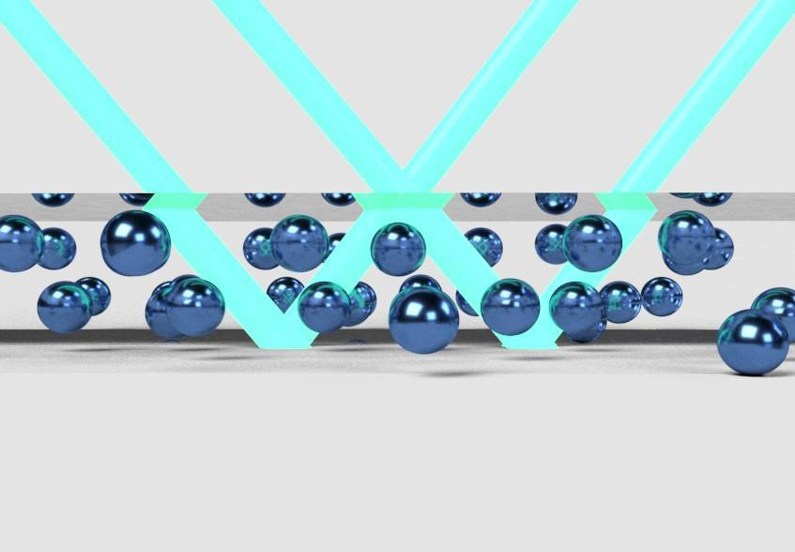

Because they record phase information in addition to intensity, holograms capture large amounts of information about a scene that would not be present in a conventional photograph. This information is encoded in the micro- and nanostructure of a recording medium. To create holograms, multiple beams of light are overlapped within a specialty photosensitive medium that reacts to the interfering light beams. The medium acts like a photographic film and records the areas of high and low light intensity as variations of its refractive index. These periodic modulations in refractive index extend through the depth of the medium. These devices are known as volume phase holograms or volume holographic gratings (VHGs).

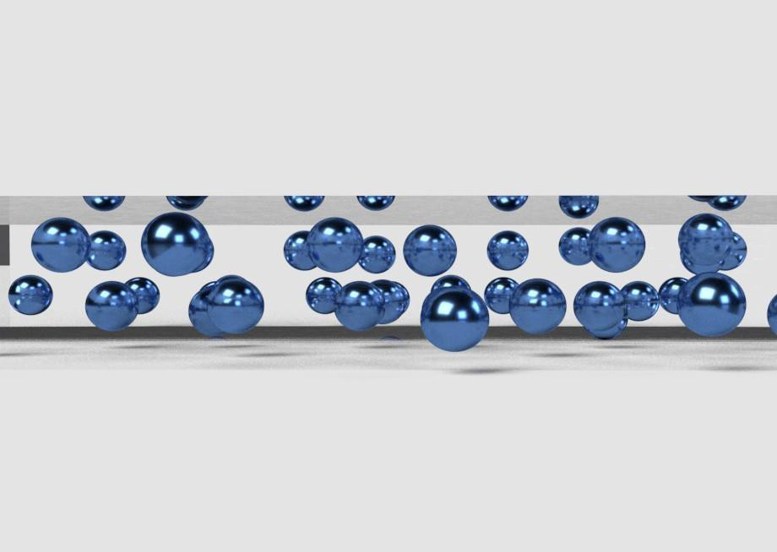

At META, holography is one of our core competencies and we use holographic approaches in a variety of applications. For instance, the key component of our flagship laser filtering product, METAAIR®, is a multi-layer holographic notch filter that is spectrally selective (only reflects a narrow band of wavelengths) and highly efficient (peak optical densities greater than OD5). The result is a laser glare protection filter that powerfully blocks the threat wavelengths without noticeably distorting the color and visibility of the viewer’s world.

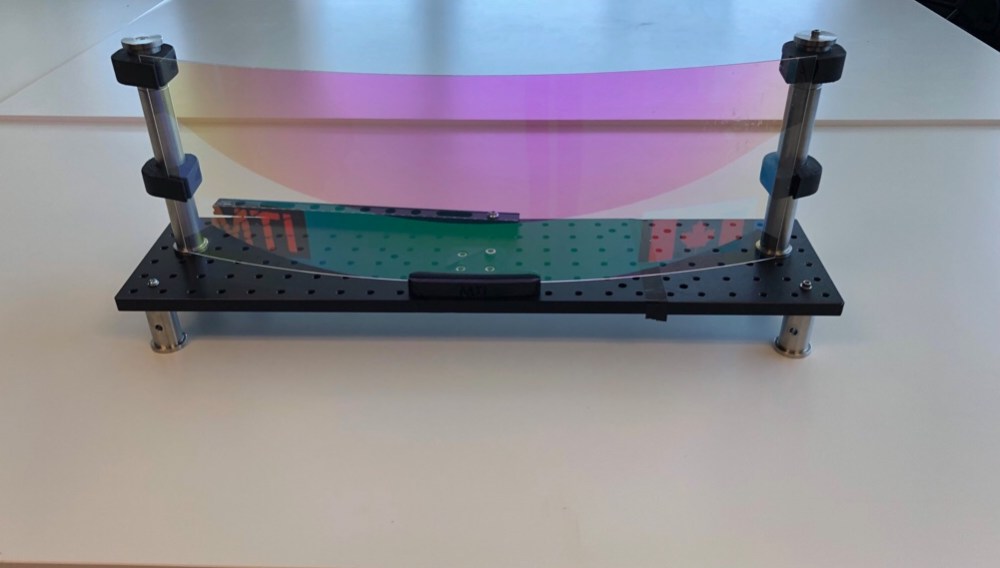

Other more complex optical elements can also be created based on holographic principles. For augmented reality headwear, we craft planar optics as optical beam combiners that integrate light from a projector with light from the real world.

More on Holographic Optical Elements

META’s holographic optical elements are based on photosensitive polymers, are custom-designed and are suitable for product integration by lamination, thermoforming, plastic injection molding and casting. META works closely with customers and suppliers to tune the properties of the photopolymer material to meet application requirements.

Below is a list of elements and features that we can offer with HOEs. These functions can be realized in a film form factor that can be invisibly integrated into what appears to be a normal eyewear lens, and in other applications where high transparency is required.

Complex Diffractive Optics provide the Benefits of Bulky Curved Optics

- HOE fabrication by direct write or replication of a master

- Multiple wavelengths within one film, e.g. RGB

- Diffraction efficiencies (DE) of 10-100% per channel with <2% DE precision

- Up to 40 mm diameter; up to 7 NA

- High transmission (>85% VLT), low haze (<3%)

Notch Filters

- Extremely large area, flexible, spectrally selective filters with high optical blocking strength.

Uniform Conformal Notch Filters

- Blocking notch wavelengths from 425nm – 650nm

- Sizes up to 800 mm x 600 mm

- Controlled filtering angle 0° – 90°

- Can be applied as a Multilayer stack

- High luminous transmission (VLT>60% per layer), low haze (<2%)

- Blocking strength up to OD6

Uniform Slant Notch Filters

- Arbitrary filtering slant angle (0° – 90°)

- Angular bandwidths up to 30°

- Sizes up to 300 mm x 300 mm

Spatially Varying Filters and Gratings

- Filters with blocking characteristics that can be controlled across the film

- Arbitrary filtering wavelength and angle

- Sizes up to 400 mm x 400 mm

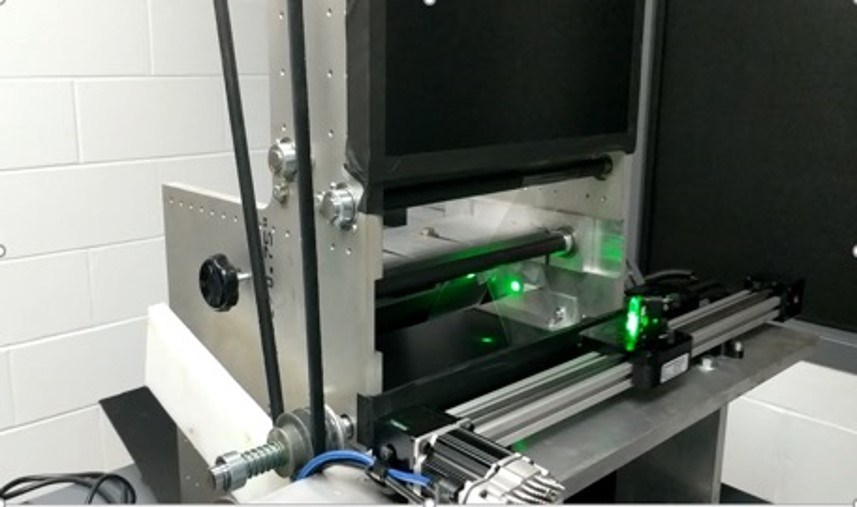

Advanced Holographic Production Capabilities

- ISO 9001-2015 certified production facility with ISO 6 and ISO 7

- Multilayer optical stack assemblies produced by scanned recording at large scale (up to 600 nm x 800 mm).

- Automated inspection stations to ensure the highest levels of product

- Industry 4.0 capable manufacturing ERP ensures traceability and conformity from raw material to end product.

Application Integration

- Application specific photopolymers developed through strategic partnerships

- Flat & 1D curved form

- Capabilities in forming, lamination, and film

- Application to a variety of substrate materials and

- Suitable for eyewear, consumer display, and automotive

- Validation and testing against international environmental and aerospace standards.

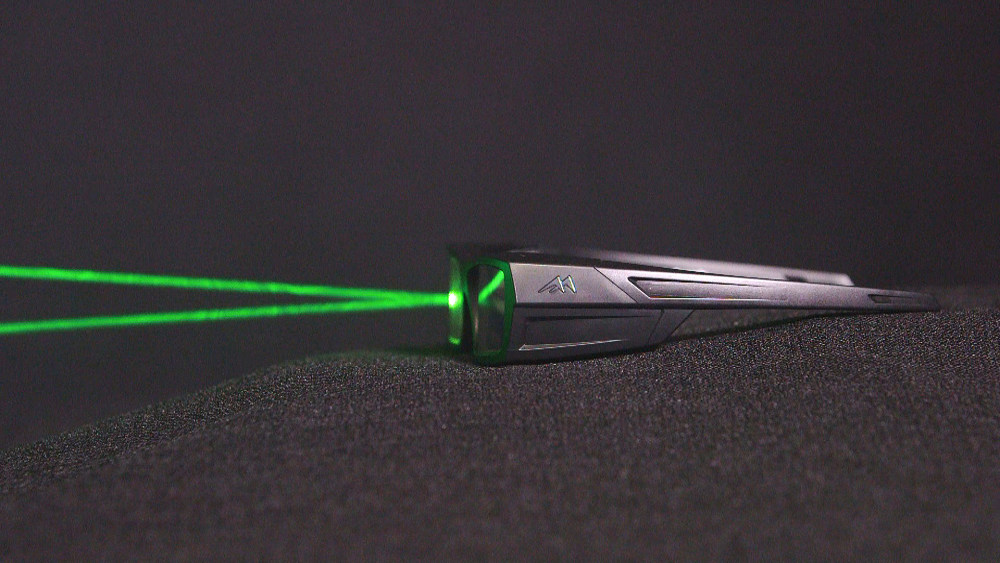

Research and Development

- Dedicated team of product development experts

- Full suite of custom and commercial measurements and characterization instruments

- State-of-the-art optical tools (tunable lasers, opticomechanics, design and simulation software)

- Can support product development from idea, to proof of concept, and then to production

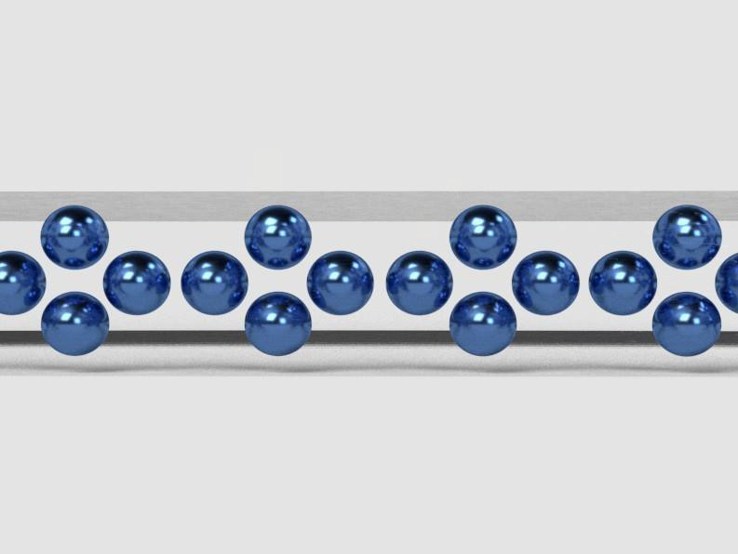

Photopolymer Material Matrix

Holographic Patterning

Re-arranged Molecular Structure

Laser filtering technology

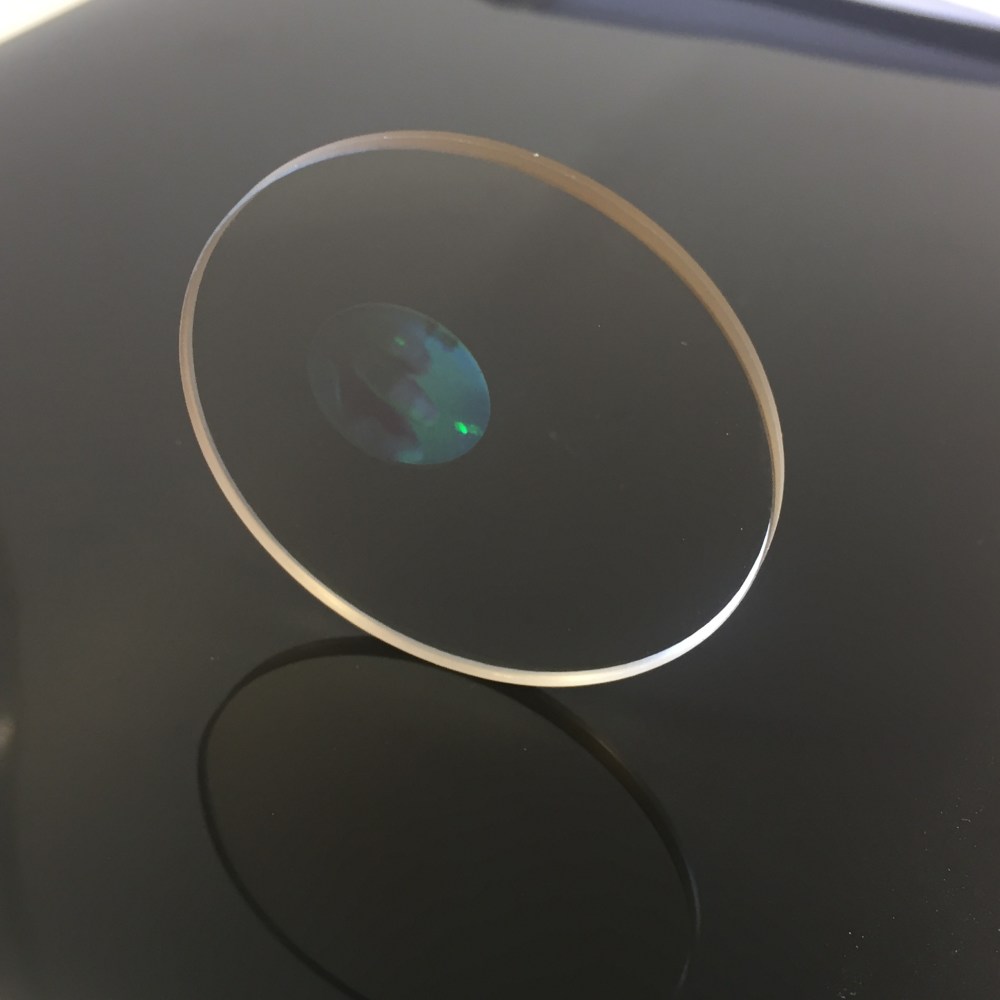

HOE embedded into a spherical lens

Holographic filter on a curved display