Enhancing Performance and Safety for EVs

Electric vehicle consumers desire increased range and fast charging to get back on the road quickly. Storing more energy relative to weight and volume and accepting higher charge rates increase the requirements for material performance, stability, and safety. Wider EV adoption demands improved material utilization along the supply chain.

META is developing new battery materials and manufacturing techniques to address all these challenges. PLASMAfusion™ high-speed vacuum coating technology has been used to produce prototype thin coated copper current collectors, significantly reducing weight. NPORE® ceramic separators feature <1% heat shrinkage for increased safety and offer superior electrochemical performance.

Coated Copper Current Collectors: Reduced Weight, Enhanced Safety

Copper foil is over 10% of the weight of a typical battery cell

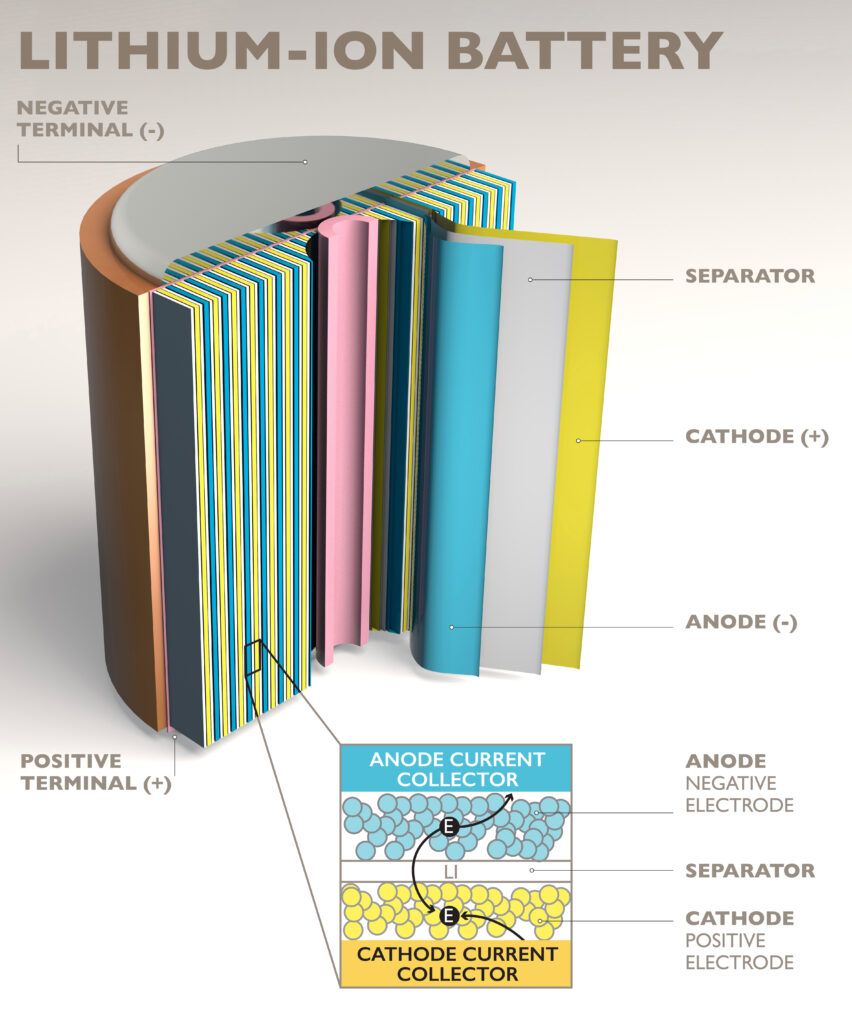

Current collectors are essential components of lithium-ion batteries, consisting of aluminum (Al) and copper (Cu) foils for the cathode and anode, respectively. Collectively, current collectors account for about 15% of the total battery cell mass and do not actively contribute to battery capacity. Al has a low density of 2.70 g/cm3 while Cu is much heavier at 8.96 g/cm3 such that Cu foil current collectors account for more than 10% of the weight of a typical Li-ion battery.

Plastic substrate acts as a fuse to impede thermal runaway

A PET/PEN plastic substrate coated with 150nm of Cu on each side promises the same functionality and cost as copper foil, while providing several benefits. Weight is reduced by ~80%, increasing energy and power density. In case of thermal runaway, the plastic melts, improving safety by retarding battery self-ignition. Lower copper content reduces the energy input to produce the battery and enhances recycling.

NPORE® Ceramic Separators: <1% heat shrinkage for increased battery safety

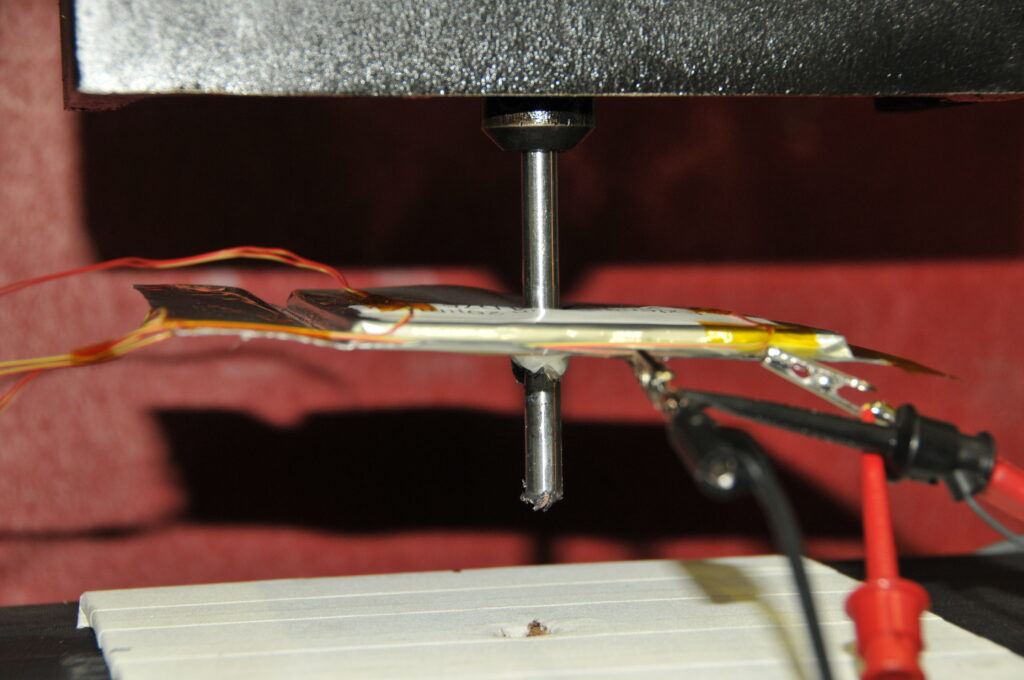

NPORE® separator prevents thermal runaway in nail penetration test

NPORE® is the world’s first flexible, free-standing ceramic nanoporous membrane separator for lithium ion batteries. NPORE® separators eliminate the use of plastic substrate, provide superior functionality and outstanding heat resistance for current and next generation lithium ion batteries.

NPORE® features include:

Thermal Stability

- Best in class dimensional stability

- 5x higher thermal conductivity vs. plastic separators

- Flame resistant

Electrochemical Performance

- Superior abuse resistance

- Rapid wet out with battery electrolytes

- 3x greater compression resistance vs. plastic separators

- Excellent electrolyte conductivity

- Uniform and narrow pore size distribution