Core Competencies

Nanotech is an end-end nanoscale manufacturer that supplies nanomaterials and nano-optic authentication technology. Our proprietary nanotechnology based design, origination, recombination, and manufacturing processes enables mass manufacturing of nanoscale materials for multiple industries. The incredible nanoscopic size and complexity of our structures, measuring only 50 – 300nm, demonstrates Nanotech as uniquely qualified to introduce new market-changing improvements such as reduction in size, increase in density, and increase in application usage through the introduction of exciting, flexible, new form factors across a variety of industries

Design

The industry demand for ‘informed nanomaterial designs’ is growing, and our team can offer nano-mechanical & structural modeling and simulation for intended applications. Our expertise includes high aspect ratio nano-structuring, multi-layer 3D structures, thin film optics modeling, diffraction, and plasmonic effects. We have built a sophisticated 3D physics and graphics software engine that supports in-house image, motion graphics and nanostructure design expertise.

Origination

Nanotech applies advanced micro and nano-optic engineering, modeling and simulation to create innovative products. We are one of the few organizations in the world to own and operate our own high-resolution, high-throughput JBX-6300 Electron Beam Lithography system housed in a secure, $65M Class 100 (ISO5) clean room facility. Our originations support structures of 50 – 300 nm size and we can also deliver lab-scale nano-imprint replication, UV casting, and thermal imprinting. All of our originations are backed by a wide range of proprietary nanofabrication techniques and equipment that is housed in state-of-the-art secure facilities.

Recombination

Nanoparticles and nanomaterials are the functional building blocks of many developing technological applications. In order to mass-produce these materials a step and repeat or “recombination” is required. Recombination at the nanoscale is extremely difficult to accomplish with consistency and without a loss in fidelity. Our recombination process is supported by our expertise in Nanotechnology, UV Recombination & Electroforming of micro and nanostructures.

Production

Nanotech’s engineering and production personnel have decades of experience in volume and specialized vacuum deposition, high precision UV casting, metalizing, device application and nanotechnology roll-to-roll web processing. Our secure production facility has an annual foil production capacity in excess of 7 million m2. Nanotech’s team can deliver materials, process capabilities, and volume production of narrow and wide web thin film and UV cast nanomaterials.

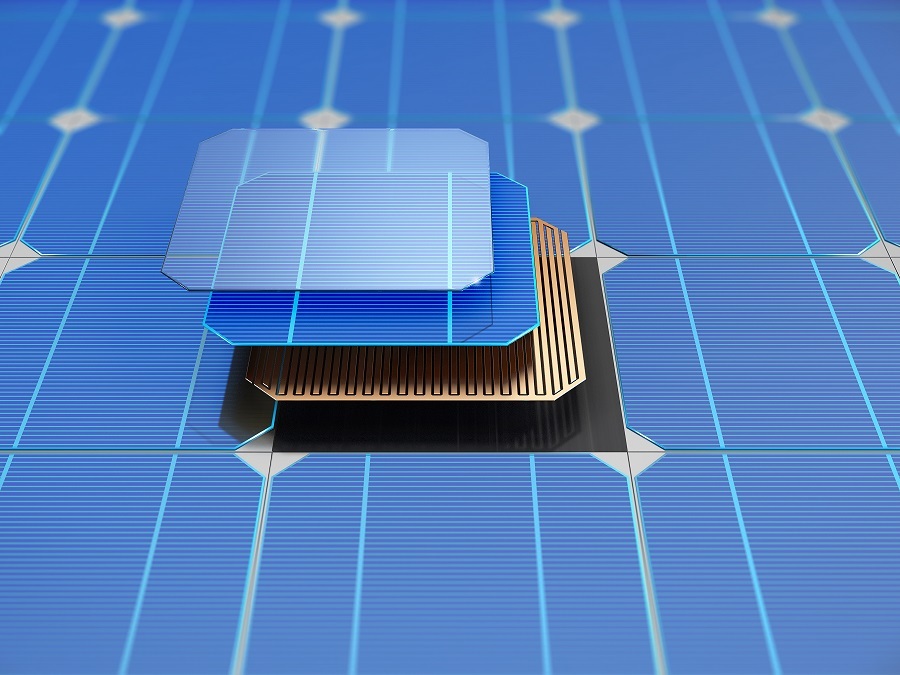

Solar Cells

The amount of solar energy that hits Earth’s atmosphere exceeds 1.74 petawatts annually, half of which reaches the surface. With global power consumption of 16 terawatts annually there is over 5,000 times more solar energy falling on the planet’s surface than our current needs. Solar energy is not an issue of scarcity, but accessibility and efficiency. Nanotech’s unique ability to design and manufacture nanostructures in flexible, nano-optic foils, we have an opportunity to reduce cost, increase efficiency, and increase application by orders of magnitude in comparison to legacy solutions.

Applications of nanotechnology include Anti-Reflection Coatings to reduce loss from back scattering reflection thus increasing efficiency of solar cells.

Benefits:

Increased density raises solar efficiency per square metre

Focusing of light to raise efficiency

Reduced size of structures & flexible form factor

Battery & Fuel Cell Technology

Rechargeable batteries are currently limited by the size, weight, and energy density of current technologies. Automotive, consumer electronics, and renewable energy storage markets are all driving battery technology innovation.

Nanotech’s expertise in complex nanostructures, metallization processes, and nanomanufacturing offer new solutions to increase battery electrode surface area resulting in increased output power.

Benefits:

Increased density to improve available power

Reduction in size and weight

Reduction in recharge duration

Sensors

Nanotechnology-enabled sensors are providing new solutions in physical, chemical, and biological sensing for a wide variety of health, safety, and environmental assessments.

Nanotech’s technology can help enhance sensors with engineered nanomaterials to deliver new solutions combining efficiency, low power, and smaller novel applications by detecting compounds on a microscopic scale.

Benefits:

Increased surface area density

Flexible form factors

Lower -power

5G & Other Antennae

Nanotechnology can deliver high conductivity without sacrificing the electromagnetic behavior of 5G or directional, passive antennas. Antennas equipped with nanomaterials have excellent radiation performance, radar absorption and scattering properties, radar detection and beam steering. Nanotech can be used to improve the efficiency of transport and wearable antennae such as Bluetooth.

Nanotechnology can be used to create custom materials and webs that deliver next generation performance for foil based micro-antennas outside windows & buildings.

Benefits:

Reduced structure sizes suitable for 5G

Increased density for greater efficiency per square metre

Flexible, transparent form factor

Carbon Capture

Nanotechnology can help clean the air by capturing carbon dioxide created during industrial processes. Nanoporous membranes can remove carbon dioxide from power plant smokestacks, without affecting the rest of the exhaust systems in smokestacks.

Smooth carbon nanotubes reduce the resistance molecules encountered and thus increase efficiency compared to existing solutions.

Benefits:

Flexible form factor

Surface area density of nanostructures to increase CO2 capture

Higher thermal stability.

RESOURCES

Visit our resource centre for product information, videos, digital media and more

UPCOMING EVENTS

Read about why we do what we do.