A Revolutionary Transparent Conductive Film

Flexibility. Conductivity. Transparency.

NANOWEB® is a transparent conductive film made of an invisible metal mesh that can be fabricated onto any glass or plastic surface. It offers a superior alternative to Indium Tin Oxide (ITO), Silver Nanowire (AgNW), graphene and carbon nanotube among other ITO-alternative technologies.

It has a nanostructured thin metal layer that is a two-dimensional mesh of continuous wires. The design of the mesh geometry allows for a highly conductive and transparent layer. Due to its high conductivity, it can operate using very little power while remaining clear and transparent. Its grid of highly conductive lines allows more energy to pass through an open area surface versus unpatterned conductive materials. The metal mesh has been created from silver, aluminum, platinum, copper and nickel, but it can be done with almost any type of metal. The transparency depends only on geometrical design of the mesh and not the type of metal material. Sub-micron lines are designed to ensure there is no visibility to the human eye.

The world’s highest-performing Indium-free transparent metal-mesh.

It has been developed using Rolling Mask Lithography (RML®). The RML process enables NANOWEB® to be produced for large-area products, devices, and films in roll-to-roll production.

The Benefits

Transparency

It is invisible to the human eye. Compared to current technologies like Indium Tin Oxide (ITO), NANOWEB® has achieved a higher level of transparency for conductive metal mesh. Due to its flexibility of design, it is able to achieve high levels of transmission and high conductivity with very low haze.

Flexible and Durable

NANOWEB®’s transparent conductor fabricated on flexible films allows for bending, flexing and folding without affecting performance. NANOWEB® also has the ability to be shaped and molded to an object, covering the surface while maintaining its properties. NANOWEB® is also light weight, can withstand extreme environments, and can be formed on large rigid and flexible surfaces.

Low Cost

NANOWEB® can be produced on a large scale, allowing the cost per unit to decrease as volume increases.

High Conductivity

NANOWEB® remains highly conductive, while maintaining its high transparency and invisibility of lines. Its level of conductivity can be modified by the type of metal used or by altering the geometric design (linewidth, pitch and thickness).

Large Surface Area Coverage

NANOWEB® can be produced to cover large areas of glass or in large rolls of film. Large pieces of the film retain the same performance as smaller pieces.

Low Voltage

High conductivity allowsNANOWEB® to operate using the low voltage power supplies currently available on transportation vehicles and planes, without the need for transformers. Small batteries or even energy harvesting devices would be sufficient to powerNANOWEB® on devices like glasses, visors, cell phones and smart watches.

Additional Benefits

- Invisible to the human eye (sub-micron lines) Low Resistivity (0.1-20 Ω/sq.)

- High transmission (up to >99%) Color neutral, low haze (<1%)

Compatibility

- Most flexible films (e.g. PET)

- Most rigid substrates (e.g. glass, sapphire) Any metals ( Ag, Au, Al, etc.)

- Large area applications

Custom Designs Available

- Sheet Resistance, Rs: <1 to 20 Ω/sq Transmission, T% : up to 99%

- Haze, H%: as low as 1% Linewidth: 0.15 to 1 micron Pitch: 2 microns and above Thickness: 50 nm to 1 micron

Note: The parameters above are interconnected.

META is the first company to dramatically reduce the amount of energy required to produce a square cm of nanomaterial products while at the same time allowing freedom of raw metal choice, enabling independence of rare earth metals such as Indium.

NANOWEB® Capabilities and Industries Benefiting fromNANOWEB®

Sensor Protection

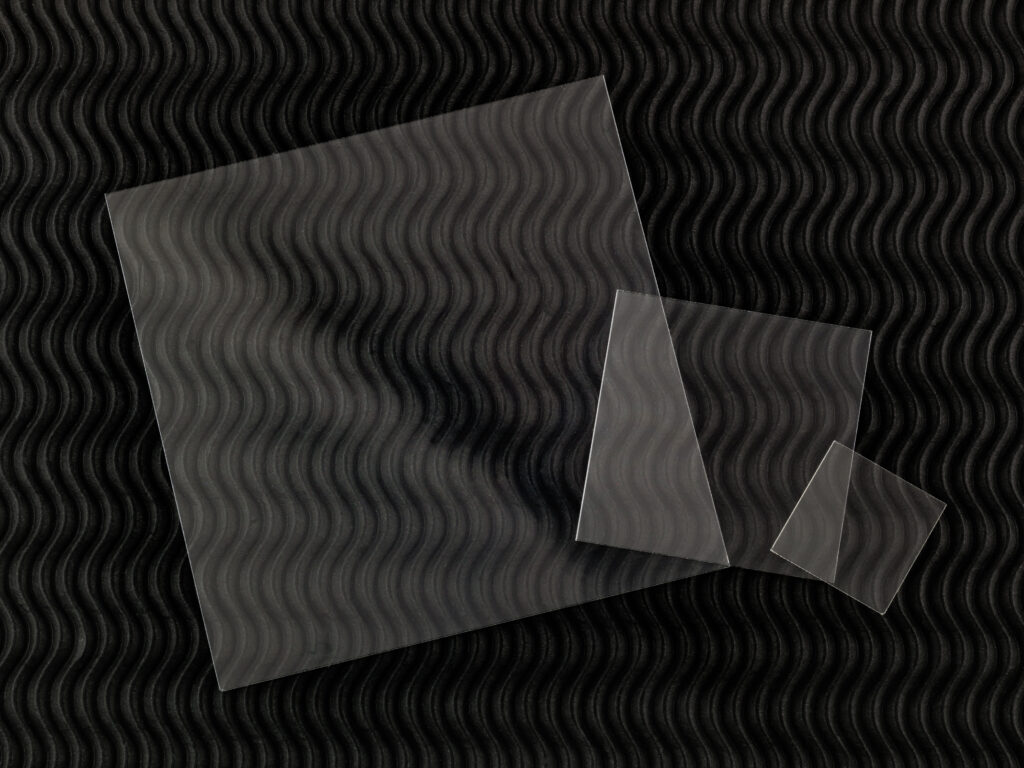

Pictured: NANOWEB® won the IDTechEx Best Manufacturing Technology Award